Atlas Copco Tools has partnered with Industrial Assembly Solutions to launch a new application which harnesses artificial intelligence (AI) and machine learning to identify risks in production before they occur.

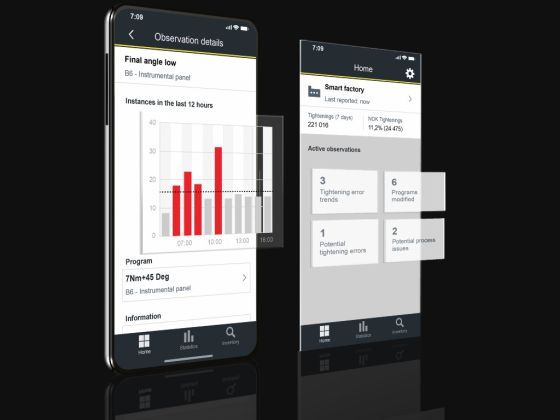

The ALTURE app (ALTernate FutURE) will use raw data captured from smart tooling and integrated controllers. ALTURE analyses this using AI and an algorithm in the app. Managers will then be provided with real-time line performance notifications, as well as any ‘Not OK’ (NOK) tightening trends and recommendations for process improvement. Feedback from over fifty of Atlas Copco’s global customers during a 12-month trial confirmed that the smartphone app was the simplest and fastest means of delivering real-time information, enabling personnel on the shop floor to counterstrike any emerging issues.

James McAllister, General Manager, Atlas Copco Tools and Industrial Assembly Solutions, said: “In the last two years, 90% of all information in the world has been created, which shows just how much data is being produced. For manufacturers, the challenge of increasing throughput that’s right first time, every time, towards zero defect production, is what Atlas Copco’s primary mission is focused on achieving. With the introduction of ALTURE, which interrogates data in real time using AI, we can provide customers with a continuous value cycle, so that any erroneous production issues are flagged before they become problematic. In this way, costly interruptions to the manufacturing process can be avoided.”

“As a strategic tooling and data services partner for some of the world’s leading manufacturers across numerous sectors, Atlas Copco is at the forefront of innovating assembly solutions which deliver safer and more cost-efficient productivity. ALTURE represents the next level in harnessing machine learning to make manufacturing more sustainable by reducing material wastage and unnecessary energy consumption, thanks to the power of data.”

Are you in the fastener, tool, fixing or related industries? You can subscribe to Torque Magazine or sign up to our weekly newsletter.