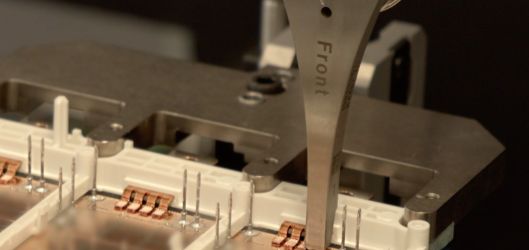

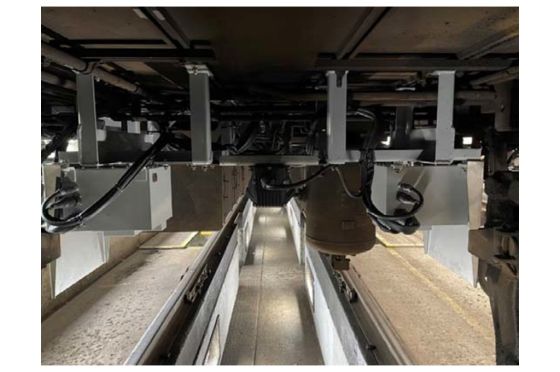

Kawasaki Track Technologies has started testing a track fastener monitoring technology in Japan. This technology, while installed on a locomotive, captures high resolution pictures and provides data for Kawasaki to utilise machine learning algorithms to identify potential track fasteners that need to be inspected and repaired.

Kawasaki employs cameras and global positioning sensors to identify potential defects with track fastening systems. When the system is complete, it will provide near real time exceptions to customers to plan maintenance.

Kawasaki Track Technologies plans to roll out similar testing in the North American freight rail industry later this summer and begin piloting the monitoring system in early 2023.