An innovative system solution by fischer now allows high loads to be transferred alongside a wide range of applications in structural timber construction. fischer’s FIS EM Plus injection mortar can be used to bond FIS A anchor rods or to bond FIS G internal threaded anchors flush with surfaces.

fischer has expanded the range of applications of its FIS EM Plus injection mortar to include bonding in wood. In addition to lasting and secure fastenings in concrete and post-installed rebar connections, the epoxy resin mortar now also transfers high loads in structural timber construction. Combined with FIS A anchor rods or the new FIS IG internal threaded anchor, load-bearing timber components made of spruce, fir or pine can be connected with FIS EM Plus. A general technical approval provides added safety.

A comprehensive range of accessories and system components made of galvanised steel and stainless steel allow many different bonded connections to be implemented in wood both indoors and outdoors with the FIS EM Plus. M6 to M30 FIS A anchor rods with variable anchoring depths and FIS IG internal threaded anchors with an internal thread of M8 to M20 can be used. Ribbed bars in diameters of 6 to 32 mm are also approved. By offering this innovative internal threaded solution, fischer offers a particularly safe method of transporting and assembling prefabricated timber components that prevents protruding anchor rods from being bent. Two components can easily be connected on site thanks to the internal threaded solution. The comprehensive range of accessories includes DD-E/DD-S centring clips, injection aides, extension hoses, dispensers and much more.

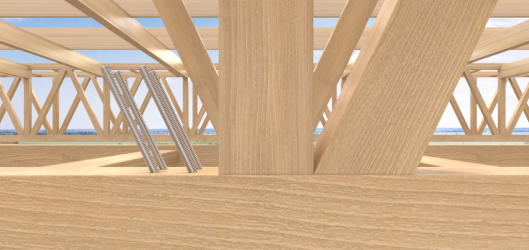

Wood components can be connected in a concealed manner using the system solution, creating new design possibilities with architecturally appealing connections. Without visible fastening points, a consistent look and the original character of the wood’s surface can be preserved.

The new fischer system solution can be used for traditional component fastenings using either pre-positioned or push through installation in just a few easy steps. After creating and cleaning the drill hole, the mortar is injected from the base of the drill hole without any air bubbles. Upon dispensing the injection cartridge, the two separately stored resin and curing components are mixed and activated in the static mixer. Next, the steel anchor simply needs to be inserted by hand using a slight rotating motion until it reaches the base of the drill hole. The fischer DD-E centring clip is attached to the end of the anchor rod beforehand, while the DD-S centring clip is placed at the setting depth level. The clips are inserted into the drill hole and make it easier to precisely centre the anchor rod.

The bypass filling method commonly used in timber construction is approved for connecting two timber components in a concealed manner and to fill deep drill holes by drilling a hole and filling it via cross hole from the base of the drill hole. In all of these applications, the mortar bonds the entire surface of the steel component with the drill hole wall and seals the drill hole.

In addition to high load-bearing capacities in structural timber construction, the FIS EM Plus also enables other versatile anchorages that offer lasting safety. Three European Technical Assessments (ETAs) and an ICC approval for the USA and countries in Asia cover fastenings in concrete as well as post-installed rebar connections.

According to the ETA, it has a service life of 100 years and, according to the Stuttgart engineering office IEA, a service life of 120 years. The injection mortar has been approved for seismic applications in performance categories C1 and C2 (ETA) or categories A to F in accordance with the ICC-ESR. It is also a safe choice for water-filled drill holes and in the event of a fire (fire resistance class R240). The epoxy resin mortar can be processed in low temperatures of up to -5°C. Its ICC approval additionally covers underwater installation. The injection mortar can also be used in diamond-drilled drill holes in concrete without requiring additional roughing up or associated procedures and tools. The FIS EM Plus has also proven to be suitable for LP/LPP concrete (general design approval) and coated concrete (general design approval), allowing it to be used for anchorages in sealing surfaces (according to Germany’s water resources act).