Hydratight has introduced an advanced electronic bolt load monitoring product for critical bolted applications.

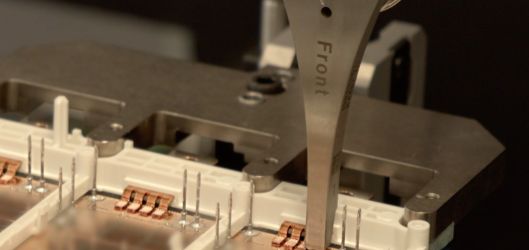

The BoltScope Ultra is a handheld device that monitors and displays elongation, stress and load on fasteners. The equipment has been designed for use in the oil and gas, nuclear, wind and power generation industries, but it can support any application where the accuracy of bolt load requirements is highly critical.

Hydratight says the BoltScope Ultra is compact, lightweight, durable and easy to operate. It also has an anti-glare screen for use in bright conditions.

Operation

An electric transducer captures the acoustic velocity of fasteners before, during and after the tightening process. The monitored data is presented on a large, easy to read color display and recorded for offline reporting and storage. The BoltScope Ultra also has a built-in fastener temperature feature via an automatic temperature probe. Thus, temperatures can be more easily and efficiently monitored by the operator than ever before.

These units have a range of automatic settings to optimize signal detection, strength and stability. The data is displayed in a format for quick recognition by the operation. A simple one key press optimises signal stability and strength, eliminating interrogation by the operator.

The product is provided with all associated accessories in a compact carrying case.

“The launch of the BoltScope Ultra represents a step-change in the technologies used for monitoring bolted joint operations," said Ian Thompson, Hydratight’s Technical Authority. "Its ease of use and adaptability across industries will increase joint integrity, leading to safety through clarity and consistency.”