From technical problem solving and tool servicing to powder coating and overseas expansion, Star Fasteners is a business keen to push into new areas. Torque speaks with Directors Daniel Starbuck and Nicola Smith for the inside story…

Star Fasteners thrives on finding solutions to the many challenges that customers send its way. Within seconds of entering Star’s still relatively new headquarters in Pinxton, near Nottingham, a clearly enthused Daniel Starbuck – Director of the company – takes Torque through one of the latest solutions the firm has come up with.

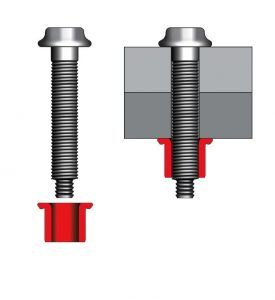

The challenge was using a strong fastener system with lightweight panels – a material increasingly being used in the manufacturing sector, including commercial vehicles. With less weight, automobiles are cheaper to run and require less fuel to get around, but lightweight panels are less well equipped to accept your typical robust fastener without incurring damage. The customer in question wanted to use Huck fasteners and came to Star – the UK’s largest Huck distributor – to see if they could come up with a solution. The team duly did – a simple, clever fix using a shim creating a dead stop on the fastener, averting the possibility of over tightening and potentially crushing the lightweight panel. Thanks to the added shim, Huck fasteners can be used on those increasingly popular lightweight panels without the risk of damage. Another problem solved.

“Customers come to us with a problem, often where a manufacturer doesn’t have a ready-made solution,” Starbuck tells Torque. “We talk to the lads on the shop floor, to the product designers and we aim to come up with an innovative solution.”

“We work on the small projects too and we’re continually coming up with new solutions. We are working with new manufacturers and trying to come up with the next thing. It’s exciting.”

Located just off junction 28 of the M1 the firm had the internal layout of the unit constructed to their own design. “It was an empty shell when we bought it,” Starbuck explains, “so we built it to our own specifications. Now we’ve space to hold an increased product range – we don’t want our customers to have to wait for product.”

The firm has grown from quite small beginnings, working out of the family home. Starbuck picks up the story: “It just started with a couple of boxes. Over time we increased our storage from a shed, to a concrete garage, then moved to our first commercial warehouse in Ilkeston. Our first warehouse seemed formidably sized at the time: We thought we’d never fill it!”

But fill it, Star Fasteners did. Director Nicola Smith tells Torque: “Moving here has opened up the possibilities. Most of the staff came with us and we value them. You have to look after them.”

Aside from being able to squeeze in more product, the added space has given Star Fasteners room to develop an all-new offering – powder coating. Coloured heads are becoming more popular, the firm reveals to Torque, with manufacturers increasingly keen to use fasteners with heads that match their livery.

Smith adds: “There’s a practical benefit in terms of corrosion resistance. Vehicles obviously are driven in all weathers and the powder coating is great for longevity and salt spray protection.”

The high quality polyester powder coating produces a maintenance-free, hardwearing finish that is resistant to yellowing and fading over time. Previously, Star contracted out powder coating, but that inevitably had pitfalls. “If a big order came through we’d inevitably be at the back of the queue, which is understandable, but not ideal for us,” says Starbuck. “There were other obstacles too. Bringing it in-house was the only way around it. Now we’re in control of our own timescales and can turn an order around for delivery very quickly.”

Not that powder coating is a simple matter. Temperature is a key consideration – “it’s as vulnerable as eggshell if you get the process wrong. Because it is in-house any issues that we had previously encountered have been practically eliminated and 1,000 is the ideal minimum to work with, but once you’ve had an initial order there is room for manoeuvre. We can colour match to our customers’ requirements and our personal service means that we can supply whatever colour the customer wants.”

Star Fasteners offer a comprehensive tool service, something it has done virtually since day one. The company stocks new tools and related consumables and also offers hire, repairs and servicing.

“It’s generally hydro-pneumatic tools that are used to install these fasteners; there’s a lot of force required so it’s important they are maintained and serviced regularly.”

The firm undertakes regular tool servicing for customers, taking care of repairs to keep production lines rolling, fasteners installed correctly and to help them adhere to their health and safety obligations. Star Fasteners like to keep abreast of the latest technology and products so did plenty of research to find an environmentally friendly parts washer: “We didn’t want to be handling drums of harmful chemicals. The unit reuses its cleaning fluid and you just have to top it up.”

Companies can hire their entire fleet of tools from Star Fasteners or can lease out just one: “If a tool develops a fault or requires servicing, that can be a serious obstacle for a business – we can step in and provide service loan tools.”

Huck is central to the Star Fasteners business. “We are the UK’s largest Huck fastener distributor. We do a lot of business in Europe and worldwide; as far afield as China.”

Huck, owned by Arconic Fastening Systems & Rings Ltd, has been working with Star on new applications – often in the context of more problem solving for customers. While the design of Huck has evolved, the original products are still available – with all Huck fasteners sporting the trademark lazy ‘H’ branding. Less historic Huck products include this year’s new Huck 12.7mm diameter Magna-Lok which has been designed as a versatile, hole-filling blind fastener. As well as having a wide grip range that can handle wide variations in joint thickness, the Magna-Lok has 360° internal locking technology that mechanically locks the pin to the sleeve. The structural blind rivet expands during installation, filling the hole and providing resistance to liquid penetration.

Then there is Bobtail, one of Huck’s latest fasteners. With no pintail to break off there is no wastage, therefore less opportunity for corrosion and no pin tails rolling around the production line. Installation is fast and – crucially for the factory floor – it’s much quieter to install. The Bobtail is a permanent, mechanically locked fastener. It is used widely in the rail sector, however the standard flanged, carbon steel 10.9 grade pin and collar enables its use in commercial chassis applications. The Bobtail is quick, easy and consistent to install out-performing traditionally used nuts and bolts, we’re told.

Other key developments for Star Fasteners include a coloured encapsulated Hucktainer. This again is controlled in house and is produced in a UV stable polymer in a huge variety of colours specified by customers.

Aside from Huck, the firm also supplies brands such as Recoil, Marson, Avdel and Scell-it, among others, and works with a variety of customers, from distributors to manufacturers – particularly in the rail sector and commercial bodybuilding market.

Star Fasteners itself has wasted no time in embracing the latest ISO 9001: 2015 Quality Management Standard. Keeping up with and sometimes ahead of the international standards and expectations is now part and parcel of the distribution sector.

Smith explains: “Distribution has changed over the years. The business is constantly evolving and it’s not really showing any signs of slowing.”

Starbuck adds: “It’s hard to imagine, but we started with hand written delivery notes on carbon paper! But we couldn’t cope without our system now.

“Traceability is a very big deal, some customers require in-depth information about materials right through to the plating process. Customers are looking to hold less stock and so require next day delivery; we hold the stocks for them. You need to look after your customers.”

Smith says: “Customers, particularly the large ones, ask that we deliver their orders in an environmentally responsible way – so more bulk orders and fewer small ones to help reduce the environmental impact.

“Our customers still like to be able to speak to a person if they need to. Support, assurance and solutions are part of the Star Fasteners brand – we have many years ‘fasteners’ experience.”

Aside from the changing distribution game, Star Fasteners clearly thrives on the challenges thrown its way.

“You never switch off and we’re not too big or too busy to work on smaller projects. We’ve had all kinds turn up in our car park: Fairground rides, classic cars…we even had an old double decker bus where a customer had pulled the handrail off and they wanted us to supply a fastener to fix it. Small projects are just as exciting to us as the big ones.

“We’re not a one-stop-shop – we are a specialist fastener distributor. We don’t do standard nuts and bolts, we don’t get into that. But never say never – if it’s good for our customers and we can make it work for us then you never know what the future holds.”

There are fresh challenges ahead for fastener firms to get to grips with, whether it’s working with those increasingly popular lightweight panels or working with the burgeoning renewables sector, in solar panels and wind turbines.

“There are new fixing solutions to be designed – it’s all moving forward,” Starbuck concludes. “It’s a good business to be in and every day is different.”

www.starfasteners.co.uk

Twitter and Instagram: @StarFasteners

This article first appeared in Torque Magazine.