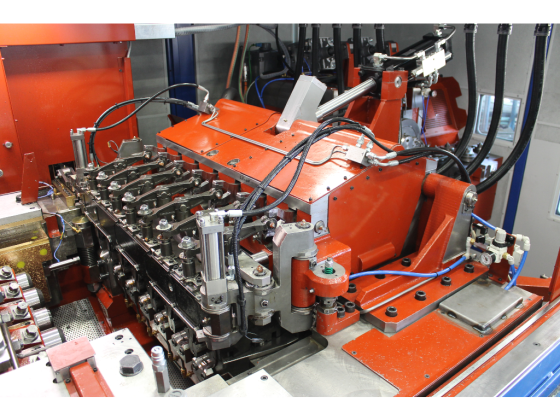

Sacma have announced the launch of its new transfer system, the new S-Transfer with HMI Setting. The new S-Transfer is now available for the 6 die progressive headers from size 4 to size 6.

The S-transfer combines the features of precision and reliability to ensure that it improves production efficiency and ease of use.

After continuous testing by R&D and industrial production, Sacma can guarantee for the S-Transfer the same reliability of the traditional version, combined with the flexibility and friendly use typical of mechatronic applications.

Through the SC Matic control panel on the S-Transfer, the user is able to set individual opening and closing time and speed, clamping force, lateral motion timing, optimizing the transport conditions for any part shape and making the machine able to run the production at the highest possible speed.

The new Sacma S-Transfer has many other features such as:

- Reduction of change-over time. For example, the setup of the transfer is done by loading the product code from the operator panel, saving time for the user.

- Higher flexibility with the independent opening function of all the fingers included in the S-transfer, which replace the option of pneumatic system to open the fingers in the mechanical transfer.

- The closing force of each pair of fingers is individually adjustable from the operator panel, replacing the traditional pneumatic system, where the closing force is the same for all the fingers.

- Timing of the transversal movement defined from the touch screen panel, without any manual intervention to be done.

- The stability and durability are also ensured by a chiller, keeping the temperature of the linear motors in optimal conditions.

Additionally, all transfer settings are stored in the PLC and applied automatically when producing the same part in the future. The S-transfer is initially available on 6 dies part formers model SP59, SP570 and SP570WF900.

Are you in the fastener, tool, fixing or related industries? You can subscribe to Torque Magazine or sign up to our weekly newsletter.