Baulking expectations that Covid would slow wind energy growth, the sector (like construction and DIY) has boomed, providing positive news for fastener, tool and fixing brands and distributors that provide for wind turbines...

2020 will be best remembered for Covid‐19, a pandemic that has disrupted and continues to disrupt the world. However, 2020 will also go down in the history books for something far more positive – as the year that wind power took a record‐breaking leap forward worldwide.

The world set a new record in wind power installations in 2020, adding an unprecedented 93 gigawatts of new wind turbines in the pandemic‐beset year – 50% more than in 2019. New installation records were recorded in China, the USA and in Russia despite expectations that the disruptive element of Covid‐19 and lockdowns would stifle growth in the wind sector.

The figures, put together by the World Wind Energy Association (WWEA) revealed that world capacity reached a total of 744 Gigawatts – sufficient to generate 7% of the world’s electricity demand.

Stefan Gsänger, WWEA Secretary General, said earlier this year: “We are very encouraged by the strong growth in the wind sector in 2020. Given that many governments become more committed to greenhouse gas‐free renewable energy sources, we are very confident that such growth will also happen in the future and becomes even stronger. Accordingly and subject to increased efforts, the possibility exists that the world gets on track to meet the goals of the Paris agreement and limit global warming to 1,5°C. The key is: Let citizens and communities around the world realise and experience the benefits of wind power.”

Renewed optimism, green hydrogen & digitalisation in wind power

Those strong numbers have helped an upsurge in positivity in the sector, as evidenced in the WEtix (WINDENERGY trend index) survey organised by Messe Hamburg in cooperation with the HUSUM Wind show. The report found that 70% of respondents believed that the coronavirus pandemic has had no effect on the wind industry, or that it actually affected it in a positive – or even very positive – manner. The share of respondents fearing a negative or very negative impact decreased since its autumn 2020 survey.

The same survey found that the mood in the European wind industry is now more positive than it has ever been (since the survey was founded). Europe’s onshore wind market has been receiving positive marks for both the respective current year and the future, while the current outlook on the offshore wind market two years from now has reached a near‐optimum level. Likewise, expectations for the North American wind market are now very positive, according to the respondents.

In terms of trends, a significant 70‐plus of respondents saw a ‘middle to very high’ likeliness that the production of green hydrogen will play a key role for wind energy over the next three years. This means that green hydrogen is now given somewhat greater importance than in the previous surveys.

Expectations for optimisation potential driven by digitalisation also improved slightly (see below), remaining at a high level for both onshore and offshore wind energy. Within this category, expectations in the offshore segment are more optimistic, leaving the onshore segment further behind. With promises from politicians (not least US President Joe Biden) to scale up wind power capacity, the supply chain for the wind energy market is forecast a strong growth period.

FOCUS ON COSTS

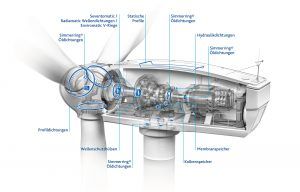

Driving down costs remains an important factor for the wind sector. With that in mind, Freudenberg Sealing Technologies has developed an advanced test procedure and simulation methodology that, in combination with the company’s Ventoguard range of elastomer materials, improve the performance and longevity of components in offshore wind turbines, so says the company.

Material simulation helps determine optimal materials and designs for wind energy applications by precisely analysing how the materials will behave over the lifetime of a turbine. The process was recently used to identify the best materials and designs available to protect turbine foundations from moisture and wear.

This article originally appeared in the June 2021 issue of Torque Magazine, which you can read in its entirety online. If you are part of the fastener, tool and related industries you can subscribe to the magazine or sign up to our weekly newsletter.